KIFFE ENGINEERING GmbH

Am Krebsgraben 18

D | 78048 VS-Villingen

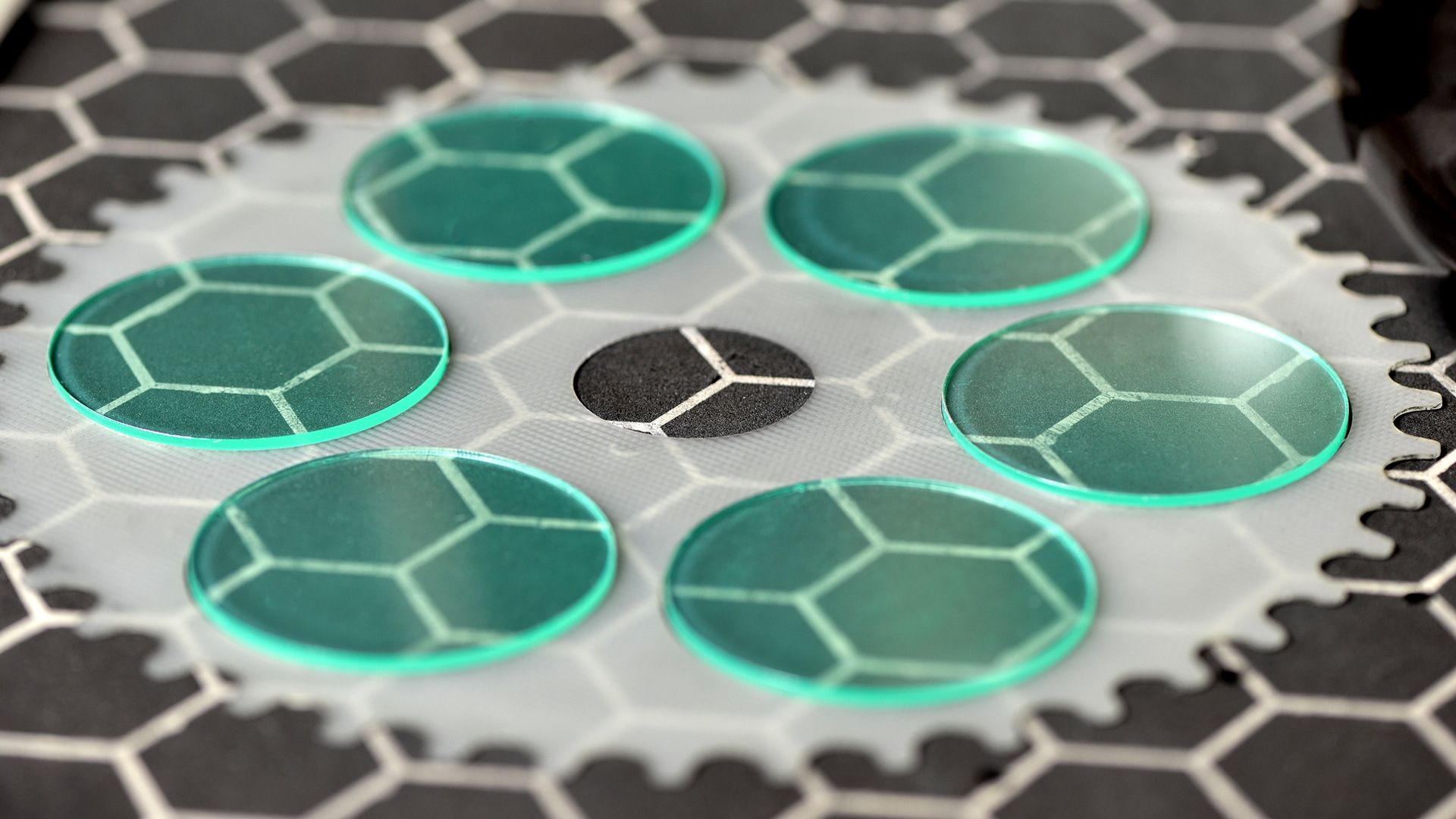

KIFFE surfacing is the first choice for a high-precision machining of surfaces:

Our expertise in precision grinding includes lapping, flat surface grinding, fine grinding, polishing, double surface grinding, one sided and double sided continuous grinding, deburring, disc grinding and laser marking.

What we offer at KIFFE

In our factory in Villingen, we offer all manufacturing processes in facing and plane grinding and are highly specialized in each of these procedures.

We choose for our customers the most efficient and cost-effective solution for surface processing.

To achieve a precise surface, processing includes the highest quality control of the machined workpieces. This we accomplish with our hydrocarbon cleaning systems.

State-of-the-art measurement technology allows us highly accurate measurement of the surface quality of the workpiece (e.g. evenness).

Our surfacing specialists gladly accompany you from the component design and process development through to series production of your parts.

We process workpieces from 1mm up to 1500mm wide in a variety of materials (steel, tool steel, stainless steel, titanium, gold, aluminum, magnesium, non-ferrous metals, carbides, engineering plastics, fiber composites, carbon fiber, ceramic, aluminum oxide, zirconium oxide, silicon nitride and sintered materials) with modern fine grinding, lapping, brush deburring and polishing machines in accordance with ISO standard.

As a competent system partner, we also offer you a complete processing and a preferred processing of your parts.

KIFFE grinding stands for the highest quality

According to ISO 9001:2015

If you have any questions or want to request a quotation, we are happy to help you – please contact us!